Pump-Off Controller Design

This article describes the basic architecture of the Oil and Gas Solutions Pump-Off Controller tags and how they are used.

The Pump-Off Controller (POC) tags are designed as a structure beneath a single tag that will allow you to control and monitor a pump-off controller device. They contain drivers that have been pre-configured with the addresses and poll sequences necessary for reading Dynacard data, setpoints and other telemetry values. Pump-Off Controllers include:

...POC-DV8 Tag

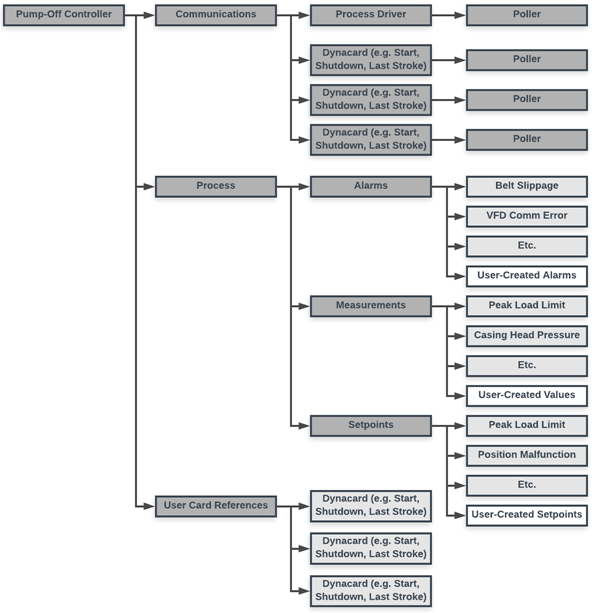

When a Pump-Off Controller tag is created, several child tags are added automatically, as shown in the following figure. Note the tags shown in white are user-defined and not created automatically when a Pump-Off Controller tag is added.

The tags created under the Process Data context are standard analog and digital tags that address a single point in the driver. They directly reference the Process Driver’s poller as their driver.

Dynacard Tags

Dynacard data is read from the device using a series of Modbus commands rather than from a single address. For example, a “read” might consist of first writing to the controller, loading its registers with the data you’re looking for, and then sending several read messages to bring back a large block of data. The Dynacard Upload driver handles all of this sequencing and overhead, but uses the Process Driver, a standard Modbus tag, to send and receive the actual messages.

If you need to customize a pump-off controller tag to read a device that is not explicitly supported in the Oil and Gas layer, refer toSequencing Reads in a Pump-Off Controller for details on how to change the sequence of reads and writes performed by the Dynacard Upload driver.

The Dynacard data read from the device is logged by the Dynacard Input tags. These tags store all the card data in the historian (Min / Max Load, Stroke Length, etc.) but currently the only data shown onscreen are the position / load pairs that make up the Dynacard graph.

Related tags: