SCADA stands for Supervisory Control and Data Acquisition.

In short, SCADA systems receive data from various inputs, process it, and display and act on that information. This automated ingestion and processing of data makes SCADA an essential component across nearly every industrial automation process.

SCADA is all around you every day and part of everyone’s day to day life – even if you’ve never realized it. Every glass of water from your tap, fuel from a gas station, plane landing on time, ship arriving at port, radio broadcast, manufactured product, radio broadcast transmitted, and watt of electricity flowing from a plug happened because of a series of SCADA systems.

Because of the many possible uses and setups, the term “SCADA” often means different things to different users. Some think of it as Programmable Logic Controllers (PLCs), Remote Telemetry Units (RTUs), and their ladder logic. Some consider their Human Machine Interface (HMI) displays to be SCADA. For others, it’s a web app that presents process data from a specific brand of networked devices.

Though every system is different, most share the following elements:

- One or more monitoring and control devices to log process data and control equipment (e.g., PLCs, RTUs, and pump controllers).

- A communication network to send commands and return process data (e.g., licensed or unlicensed radios, Ethernet, cellular, landlines).

- HMI software to provide operators with a graphic representation of the process.

- A database of I/O points (tags) that define the objects in the system.

- An alarm management system to allow operators to view and acknowledge alarms.

- An notification system to disseminate alarm information to remote users via SMS text message, email, voice -to-speech, or pager.

- A database of historical process information logged by the system.

- Trends and reporting tools to derive insight from historical data.

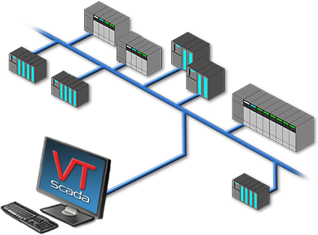

Organizations such as water & wastewater utilities typically have monitoring and control sites spread over a wide geographical area. SCADA systems use Human Machine Interface (HMI) software to poll the remote telemetry units (RTUs) at each site via radio. The system stores this information in an historical database and uses it to automate various aspects of the physical process. Users interact with the system via a series of HMI display pages.

The Changing Role of SCADA

Originally, many companies and utilities began adopting SCADA systems to replace ‘sneaker net’, a time-consuming and error-prone process where workers travel to remote sites to record levels and operate equipment by hand. SCADA systems automatically pull process data from each site and store it in a central historical database that populates displays, trends and reports in the HMI. Based on this information, Operators can use the SCADA application to operate remote valves, motors and pumps without stepping outside the control rooms. No more missing or estimated readings. No more spills because it was unsafe to travel to a site during a weather event. Better yet, staff time could be better spent on preventive maintenance.

Over time, the perceived value of SCADA systems began to focus on exploiting the ever-growing database of historical data seek opportunities to increase efficiency and extend the life of their hardware.

Modern SCADA

SCADA systems have evolved significantly over the last 70 years. They today need to be highly flexible, powerful, scalable, and be rock-solid reliable. With lives and billions of dollars on the line, SCADA has never been so important to so many people.

Modern SCADA incorporate of a wide array of technologies, including live Internet connectivity, fully redundant and hot-swappable components, HTML5 web interfaces, and even augmented reality.

VTScada continues to be a world leader of modern SCADA Systems, and is entrusted to provide clean water to millions, power of oil & gas production worth billions, and keep the world on time and moving. VTScada provides the robust features, reliability, scalability, and features required of the world’s most demanding SCADA applications.