Project Completed by Curry Controls Company

Project Completed by Curry Controls Company

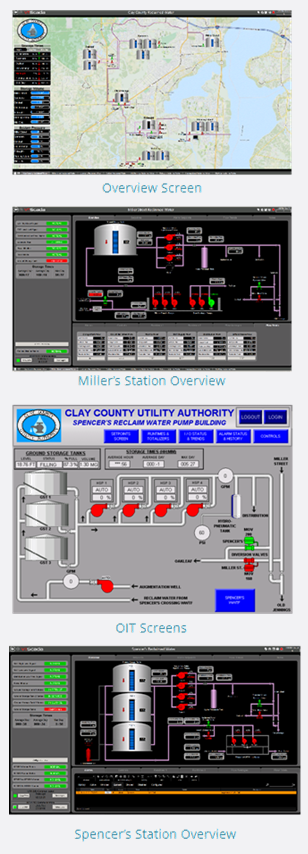

Clay County, located in Northern Florida, has a population of almost 200,000. In April 2016, Clay County Utility Authority (CCUA) needed a new SCADA system to monitor seven reclaimed water sites that the Authority uses to determine water storage times, using this data to route water from site to site. VTScada was selected by CCUA and their engineer. The new system, installed by Curry Controls, finally lets CCUA see the whole system and identify problem areas.

Project Overview – The CCUA Reclaimed Water SCADA System project is intended to provide monitoring and some control over seven existing reclaimed pump stations throughout Clay County. The existing system had no SCADA and worked primarily on local control. The purpose of this project was to gain a better understanding of where most of the reclaimed water is being used with a primary goal of maximizing storage and the utilization of the reclaimed water. The addition of the SCADA application increases system reliability and alarm response time. In addition, volumetric calculations for storage and flow averages were programmed to provide operators with valuable real-time data which shows if the storage tanks are gaining or losing volume with time left to empty. This provides operators with a quick real-time understanding of the re-pump system.

Project Overview – The CCUA Reclaimed Water SCADA System project is intended to provide monitoring and some control over seven existing reclaimed pump stations throughout Clay County. The existing system had no SCADA and worked primarily on local control. The purpose of this project was to gain a better understanding of where most of the reclaimed water is being used with a primary goal of maximizing storage and the utilization of the reclaimed water. The addition of the SCADA application increases system reliability and alarm response time. In addition, volumetric calculations for storage and flow averages were programmed to provide operators with valuable real-time data which shows if the storage tanks are gaining or losing volume with time left to empty. This provides operators with a quick real-time understanding of the re-pump system.

Eric Sullivan, Project Manager with Curry Controls describes the system, “Some of the distribution and altitude valves were modified, allowing the operators to adjust opening and closing based on operator tank level set points. This helps to automatically redistribute the water to fill other tanks when the local tank is full, saving man hours and reuse water from being wasted.”

“A secondary benefit was to add the analytical instruments to the new SCADA system allowing for trending and alarming for compliance at several wastewater facilities, giving the Utilities Manager insight into the overall operations.”

System Hardware Upgrades – Under this project, Curry Controls added six new RTUs and two remote I/O panels, instrumentation, altitude valve modifications, network equipment, and electrical installation to implement the new VTScada monitoring system to the seven existing plants. Two of the plants had existing RTUs that needed to be modified to include the additional network equipment and field devices.

VTScada Software and Servers – The SCADA system has redundant virtual servers with 5,000 I/O tags and unlimited Thin Client users with the primary server installed at CCUA’s administration building. The system utilizes VTScada’s CIP driver to communicate with the PLC. The plant’s screens were built with standard navigation and structure, minimizing differences to process piping and instrumentation.

The Operator Interface Terminal (OIT) screens were programmed to allow the same control from the local RTU. Although not as powerful as VTScada, Curry Controls duplicated as many of the features as possible. “I have personally been using VTScada for 14 years and have been involved with many installations across Florida,” says Jennifer Waymire who is an experienced Curry Controls VTScada programmer. “We have been using VTScada with Motorola PLCs, M340’s (DNP3), and Compact Logix. Most of the recent systems are on a cellular network; VTScada is wonderful to work with and has built-in features that other HMI’s require you to create.”

System Communications – Sullivan adds, “The system communicates across the County using cellular communications on CCUA’s existing Verizon account. VPNs were set up between the cellular devices and the VPN endpoint. This helps provide a more secure connection to the remote sites.”

PLC Platform – The RTUs were built with the Allen-Bradley Compact Logix platform. The RTU included a local OIT connected by Ethernet to the RTU network switch. The connected equipment included new instruments to monitor flow, tank level, and pump status signals for the re-pump stations.

Project Team – The CCUA Reclaimed SCADA project was completed in approximately one year and CCUA was very satisfied with the project design, programming, and installation.

The following is a list of the project team members from the engineering firm, the Authority, and Curry Controls:

- David Lasseter (Engineer)

- Darrell Damrow (CCUA Project Manager)

- Dennis Martin (CCUA Utilities Supervisor)

- Eric Sullivan (Curry Controls Project Manager)

- Donald Schlicht (Curry Controls P.E. PLC Programmer)

- Jennifer Waymire (Curry Controls VTScada Programmer)

- Mike Neumann (Curry Controls Programmer)

Project Testing and Challenges – The SCADA system and control panels were fully factory tested while at Curry Controls’ panel shop. The cellular communications allowed the servers to be fully programmed while they were installed at their final location in the CCUA administration building. As a result, Curry Controls was then able to factory test the panels while remotely logged into the CCUA’s server through the cellular communications from their office over three and a half hours away.

administration building. As a result, Curry Controls was then able to factory test the panels while remotely logged into the CCUA’s server through the cellular communications from their office over three and a half hours away.

During the factory testing it was discovered there were erroneous alarms being reported to the SCADA system while the panels were sitting for long periods of time on the factory floor. These alarms were not caused by a legitimate I/O condition. Sullivan describes the technical support he received from Trihedral, “After trouble-shooting the problem, we reported it to Trihedral and their support was outstanding. They were able to login remotely and trouble-shoot the driver that was causing the problem. It took several revisions to the driver, but we were able to completely solve a major problem before the panels were shipped to the sites. This effort saved thousands of dollars in potential issues by identifying a problem that would have resulted in trips all over Clay County investigating false alarms.”

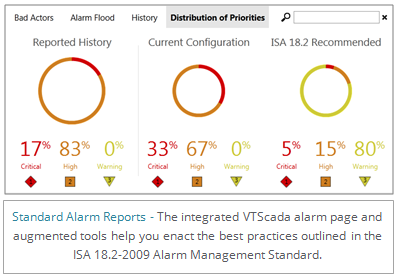

After the system was installed and operational, the customer reported that too many alarms were coming in. Curry Controls worked with the engineer in a screen sharing application and was able to use the new built-in alarm reporting tools to see which alarms were the worst offenders. Sullivan explains, “Utilizing the click to trend tools, we were able to drill into problem areas and identify a variety of issues with the new system. This allowed us to identify issues with hardware that previously had gone unnoticed and also provided insight into operational issues with set points and procedures. Small changes allowed for us to reduce the alarms to acceptable levels.”

Future Project – With the success of this project, CCUA has seen value in the new SCADA system and plans to expand its use to other CCUA departments.

About Curry Controls – Curry Controls is a systems integrator located in Florida. We have been in business since 1972 designing and building controls systems for all types of industries. As a complete systems integrator, we provide UL panel shop fabrications, electrical installations, PLC programming for many platforms, SCADA programming for various SCADA platforms. We are an Advanced Certified Solution Provider for VTScada. For more information on Curry Controls please visit: www.currycontrols.com

| Try It For Yourself Download the 90-day Trial |

For More Details Jennifer Waymire 863-646-5781 – jlw@currycontrols.com |

Images used with permission.