A VTScada Heavy Industry Case Study by Neundorfer, Inc.

Based in Willoughby, Ohio, Neundorfer Inc. is a consulting and engineering firm that has been creating customized solutions to improve emissions and increase the efficiency of air pollution control equipment. Over twenty years ago, the company was seeking a controls software package that would allow them to create a standard reusable application that they could easily customize for each of their customers. In this Q&A Neundorfer President Steve Ostanek and Computer Engineer Spencer Tibbits discuss the precipitator optimization application that they developed in-house using VTScada software by Trihedral.

Chris Little – Welcome gentlemen. Can give us a brief overview of Neundorfer and their work with precipitator optimization systems?

Steve Ostanek – Neundorfer has been involved with heavy industry, primarily around air pollution control equipment for nearly 45 years. We are consultants and engineers who create customized solutions to improve emissions and increase efficiencies in these heavy industrial processes.

Spencer Tibbits – These systems connect to devices in the field like rapper and voltage controllers. They allow you to monitor and set programs around performing the best task at hand in terms of collection efficiency and making sure that we’re not out of opacity limits and things like that. We created proprietary in-house controls for rapper controllers such as the MVC-IV and the MicroRap. We built our own communication drivers to these devices using VTScada software by Trihedral. The system allows us to log data every five seconds and get an indication every time rapper is hit. We have performance optimization tools and a variety of programs that we can set up around each piece of equipment. We even have our own DCS package that we have set up multiple times to pull data into customers’ Pi databases, so they can have it at the plant level as well.

Chris – When you say, “when a rapper is hit”, what does that mean?

Spencer – A rapper is a 20-pound magnetic slug. Once energized, it is dropped and picked back up using our rapper controller. We developed our own controls to program when it should rap, how often it should rap, and see when it is about to wrap.

Chris – Can you tell us more about how you are using VTScada software in this process?

Spencer – VTScada provides us the tools to build our own solutions, while utilizing all the standard features it provides. VTScada allowed us to build our own custom OEM layer that we can use as the basis for numerous custom applications for our customers.

Steve – In the late 80s, early 90s, there was an emerging need to interface all these devices that Spencer talked about. On a particular precipitator, there could be hundreds of devices and in a particular facility there could be multiples of that. As emission standards were getting tougher, our clients needed a better way to get data from the equipment and do something with it. We tried to create applications in DOS. Then Windows® came around and afforded us the ability to do things with graphics. It just seemed clunky. In the late 90s we met Patrick M. Cook at Trihedral. He told us that there was a tool out there that could make our lives easier. We looked at how VTScada could help us in our plant integration efforts in these industrial settings. For us, the challenge was trying to take these devices that each operated as their own island and integrate them into a plant. We had to create the means of interfacing each device with plant DCS systems. With VTScada everything including the communication drivers were already packaged in there. That made it easier if someone wanted us to interface to an Allen Bradley or Modbus device or something like that. We didn’t have to create it; it was already done. Also, it helped that the data historian was built in too. That made our lives easier when we’re trying to do this kind of integration. Over the last few decades, we’ve been able to build on top of this OEM layer and increase functionality by adding more troubleshooting and diagnostic tools that help our customers optimize their equipment.

Chris – Spencer, tell us a bit about the kinds of features that are included in these applications that are rolling out to customers.

Spencer – As Steve said, we interface with over 100 devices. Precipitators can have as few as six voltage controllers and as many as 120. VTScada allowed us to create our own voltage controller tag type in our OEM layer. That means, from a scalability standpoint, we can add 100 of them and get them up and running and commissioned very quickly. It’s the same with the rapper controls. We have systems with one rapper controller up to eight. Our custom layer can scale. We don’t have to spend time writing this over and over again, for all the different devices we have handled.

Chris – Spencer, would you show us an example of one of these applications.

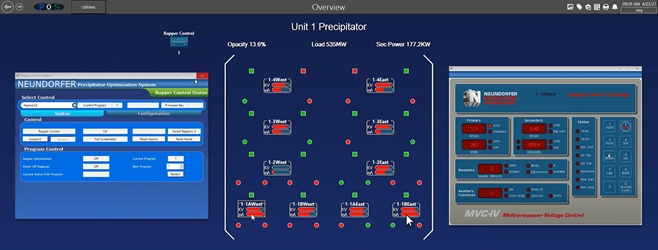

Spencer – Okay, so this is the general POS layout (page 2, top, center), it’s a top-down view of the precipitator. Here are the voltage controls that we have. If you hover over them, it brings up the control panel that you would see out in the field. It provides full access to what’s out in the control panel (above, right). You can change settings and stop and start the voltage control. These are also the rapper indications. If I hover over one, that lets me know that this rapper has hit, and then let me know when the next one is ready to hit.

Spencer – We can also go to our rapper control where we can do programming and check the control status. There’s a lot of things that we can tailor around the precipitator in terms of power off, rapping, and specialized rapping. We also built in an oscilloscope (below, left). It’s just like a regular digital oscilloscope. It allows you to see triggers, start and stop the scan and do different waveforms. It’s really nice for diagnosing the actual voltage control in the field, as opposed to bringing a handheld oscilloscope out.

Steve – An oscilloscope is a very valuable troubleshooting tool. There’s a significance to having a built-in oscilloscope and its around safety. These controllers are on individual cabinets, and inside these cabinets is 480 volts. The traditional method of hooking up an oscilloscope is that you have to open the door to the cabinet. Of course, everything that you want to attach to is in the back of the cabinet. To reach them you must potentially break the 480V plane. An operator or technician would have to get up, walk out, open a cabinet, and potentially get exposed to the dangerous situation. The oscilloscope function allows us to do things without even having to go to a control room. Now, you can just sit at a computer and look in this scope trace. You can look at it remotely as well [using VTScada Thin Clients]. That was a huge tool. It’s one of those little things that you’d think was no big deal but from an electrician standpoint it’s a pretty big deal.

Spencer – We’ve incorporated chart effects. And we’ve made a 3D graph (above, center) so you can see the lanes and how they’re running and click on different sections. You can go back historically with data. It’s a nice helpful visualization tool for our consultants and customers. As we mentioned earlier, we have a DCS table already built. This one’s for Modbus. It makes for a quick and easy setup for customers to attach to using the drivers that have already been established by VTScada. We like to think that our solutions are very plug and play. We do the work of getting it laid out and creating the HMI layout, then we just turn it over to the customer and they plug in their DCS communications. We run the field wiring out to the devices and it’s ready to go.

Chris – Do you use the built in VTScada trend viewer?

Spencer – Yes. So, we can easily open a pop up click trend (above, right). Here, we’ve pulled out an individual voltage control. If the operator starts and stops the TR it triggers a note into the notebook. It’s very helpful for diagnosing things, especially if we have customers utilizing the security credentials that we’ve provided, for different operators. The trending is absolutely wonderful. We live off the trending.

Chris – I’ve been working with Trihedral for about 11 years and Neundorfer has been a household name throughout that time. I’ve seen many really impressive looking screens, so it was a pleasure speaking to you in person and getting to see that application in motion. Thanks for joining us today.

For more information about products and services provided by Neundorfer, visit https://www.neundorfer.com.