VTScada Case Study: City of Lake Worth Beach, Florida

The City of Lake Worth Beach (CLWB) Electric Utilities serves the needs of over 27,000 residential and commercial customers located between West Palm Beach and Boynton Beach in southeastern Florida. The utility owns and operates a variety of generation resources that includes diesel generators (M-Units or MUs), a solar plant, combined cycle generation, steam units, and a grid tie with FPL (Florida Power & Light). In 2020, the utility engaged Schweitzer Engineering Laboratories Engineering Services and Energized Power Engineering to replace the SCADA application for their aging electrical substation. George Guirguis of CLWB describes how the new system, based on the VTScada platform by Trihedral, is more scalable, costs less to support, and helps improve operator response time by using the latest High Performance Graphics (HPG) screen design principles.

The SCADA Integration Team

“This project was a collaborative effort between Schweitzer Engineering Laboratories Engineering Services (SEL ES) and Energized Power Engineering (EPE),” says George Guirguis, the utility’s Transmission & Substation Engineering Manager. He oversees a team of engineers responsible for automation and SCADA integration projects. He is also the sole owner and manager of EPE, a consulting firm focusing on electrical engineering in southeast Florida. SEL ES is a worldwide engineering and consulting firm that provides complete protection, automation, communications, and metering solutions for critical electrical infrastructure.

The System Being Replaced

- Number of sites monitored: 11 substations

- Number of SCADA servers: 2 redundant servers – primary and backup

- Number and type of PLCs/RTUs: 11 SEL RTACs (Realtime Automation Controllers)

- Number and type of radios: 11 SIEMENS WiMAX 3.655 GHZ and Fiber

- HMI software being replaced: OSI

Problems with the Legacy System

“The original SCADA platform was very outdated and not user friendly or intuitive,” says Guirguis. “Making changes or adding new points was very cumbersome and extremely time consuming which was a problem for an electric utility that was expanding its automation and undergoing many upgrades in their substation environment. With the turnover of an Operation Technology support person, the in-office staff didn’t have the proper training to maintain or develop new points. Also, the cost of training and support was very expensive and was only really used in emergencies.”

Increasing Response Time Using High Performance Graphics

“We wanted to enhance the way an operator drives the system by making it more intuitive. To reduce response time, we chose to employ High Performance Graphics (HPG) where abnormal data is displayed in a manner that stands out from normal data. One of our goals for the new system included scalable and modifiable widgets that tailor to the equipment type or objects. That allows for equipment of similar function (i.e., circuit breakers, reclosers, transformers) to have the same look and feel across the fleet in the system.”

VTScada Software by Trihedral

“The team evaluated software from multiple vendors for cost, performance, ease of maintenance, etc.” says Guirguis. “We chose VTScada by Trihedral because their in-office demo proved to meet all the needs and wants for the electric utility, the cost of one year’s “platinum support” from our existing platform exceeded the cost of a whole new VTScada system, and also because it was already in use in the CLWB Water Plant.” EPE is a VTScada Certified Solutions Provider.

The Design/Development Process

Work on the new system began in January 2020 and ended in May 2020 with only minor COVID-related delays. “During the design phase, I was responsible for all RTAC device programming and new data assignment schedules,” says Guirguis. “I designed how the system should behave, operate, and interact with the operators using substation pages, and control pages for individual equipment. The tiered design displays more data and control options as the operator dives deeper into a specific piece of equipment. Operators can use VTScada Hotboxes to quickly navigate to related pages and equipment.”

The Completed VTScada System

- Scalable Licensing – “We purchased a 25k tag VTScada software license for a system with 11 substations and just over 100 relays or IED’s (Intelligent Electronic Devices),” says Guirguis. VTScada is priced, in part, based on the number of I/O points, or tags. This tag limit can be easily increased as the system grows by updating the license key. Integrated optional features, such as Thin Clients and remote Alarm Notifications can be unlocked in a similar fashion.

- Redundancy – “This system currently runs on a primary and backup server.” VTScada allows any number of additional redundant servers to be added as needed. The order of automatic failover is determined by the distributed VTScada Server List. Each configured redundant server automatically synchronizes with the primary such that each one is an up-to-the-second backup of the entire application including Historian, configuration history, alarms/events database, I/O database, and user accounts.

- Reusable Tag Structures – “One of VTScada’s greatest benefits is the ease of duplicating an already built object to quickly set up a new substation or piece of equipment,” says Guirguis. VTScada’s I/O Tag Browser is hierarchical, allowing developers to model complex real-world objects like lift stations by nesting child tags within parent tags. Parent tags can contain any number of child and parent tags. These structures can be easily converted into a reusable VTScada tag types. “Once the necessary objects are built, drag and drop the building blocks and link to new equipment. Any change made to the object is carried out to every instance of that object, eliminating editing every point that uses that object.”

“To accommodate this object-oriented approach to data collection, we restructured entire RTU points list/map,” says Guirguis. “This facilitated a standard list for each object type that can be parameterized (scanning turned on/off) for each point. This was extremely beneficial as many of the same object types differed in manufacturer and style, yet in the VTScada realm, it provided a familiar pop-up page for which an operator can confidently view and operate.” - Drag-and-Drop Screen Development – To create customized screens, VTScada features a built-in graphic development environment called the Idea Studio. It includes hundreds of industry-specific images, shapes, and data-driven widgets that can be easily dragged and dropped into place and aligned. “The Idea Studio is very powerful and intuitive, allowing for sophisticated one-line designs that make it very easy to navigate, view, and control,” says Guirguis.

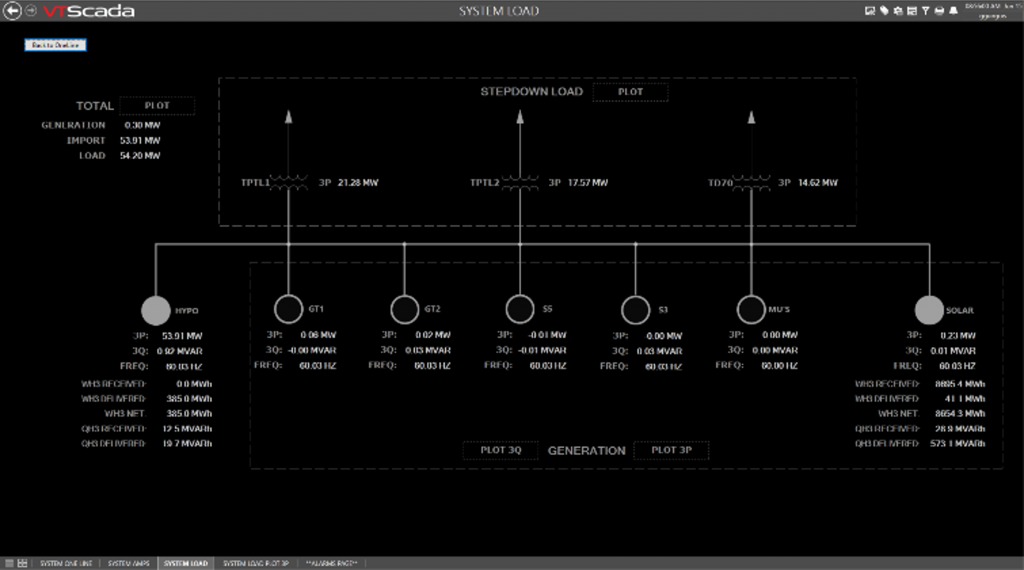

- High Performance Graphics (HPG) – As described in the ISA101: Human-Machine Interfaces Standard (https://www.isa.org/standards-and-publications/isa-standards/isa-standards-committees/isa101), HPG allows operators to more effectively monitor large systems. Rather than displaying raw values, HPG screens draw the eye to sites and equipment where process values are deviating from acceptable norms. The VTScada Idea Studio includes a wide variety of pre-made HPG widgets. Additionally, the new VTScada I/O Tag includes variables that allow these widgets to display important context information.

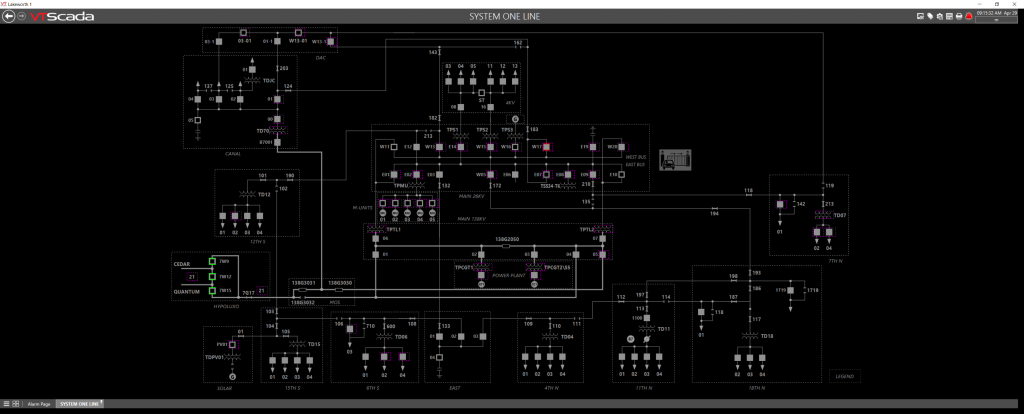

The team used the Idea Studio to create their own widgets for electrical systems. “Once I worked out the standardized details for our reusable HPG screen objects, SEL ES translated them into working widgets and assembled the model. HPG features have proven crucial in reducing reaction times by operators when responding to an event,” says Guirguis. “Abnormal conditions that need to attract attention are easily visible in a sea of normal data that can be ignored. For example, the System One-Line page (Screen 1 above) that we developed provides a complete system view illustrating the current configuration of the network as well as capturing events as they unfold.”

The Testing Process

“We initially used the SEL Realtime Automation Controllers to simulate data during application development,” says Guirguis. “Once deployed, the VTScada and OSI systems were run side-by-side to ensure that the data was accurate on both systems. We tested quality control and data assignment in View Only mode until the new system was fully validated.”

Plans for the New System

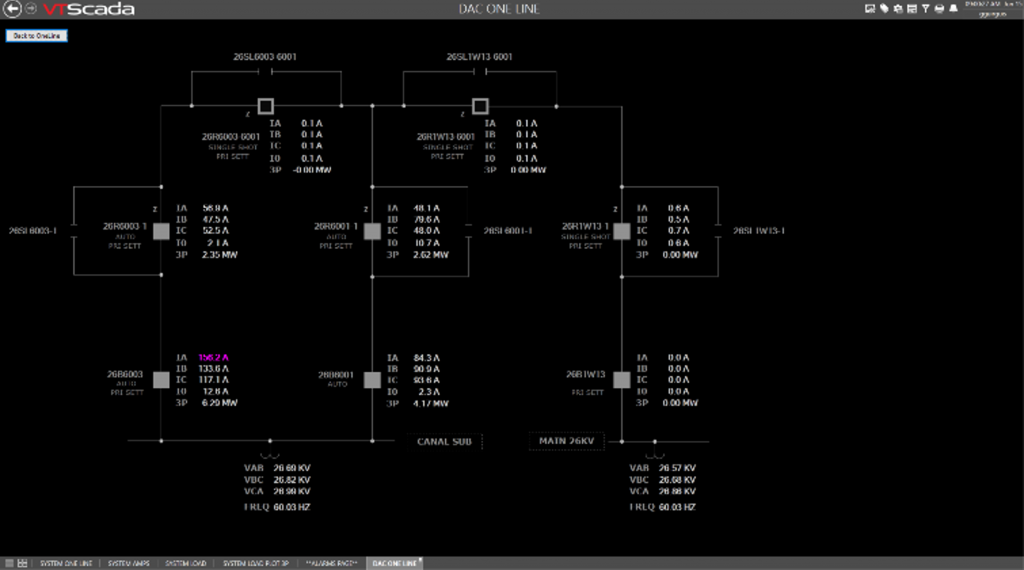

“We are currently rolling out a Distribution Automation & Control system (Screen 4) that adds intelligence to the electric network,” says Guirguis. “This involves adding more circuit reclosers to replace field switches. VTScada does a great job displaying the DAC network and associated control and statuses.”

Advice for Companies Evaluating HMI/SCADA Software

“I would highly recommend VTScada,” says Guirguis. “It is important to have a system that is scalable and adaptable without a significant time investment. With powerful built-in tools right out of the box, the sky is the limit for the system integrator and their clients. Since it is intuitive, company personnel can maintain their own applications in-house if they wish, saving on support from their integrator; especially for minor fixes or improvements. The price point is also a consideration,” says Guirguis. “VTScada solution and maintenance & support are very reasonable, so justifying the investment was trivial.”